Tackling uranium mill effluent treatment with chemistry

Saskatoon student models mill processes for a cleaner future

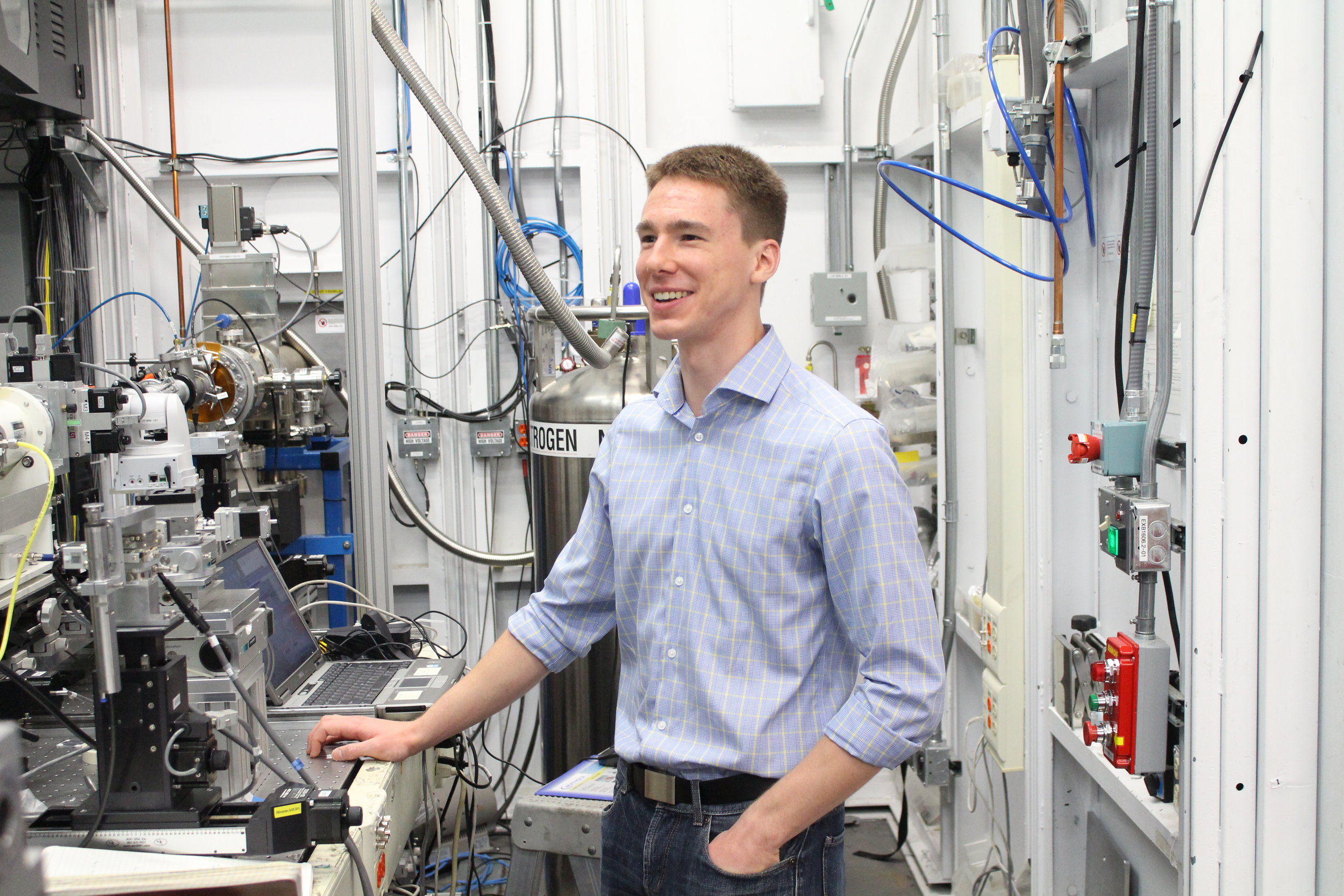

Jared Robertson grew up admiring the Canadian Light Source synchrotron from afar. Today, the University of Saskatchewan student uses it to address some of the uranium industry’s most pressing questions.

“It’s been exciting to do some amazing science right in my backyard,” says Robertson. “I grew up in Saskatoon, knowing what the CLS was, and when I went to university it was kind of like this magical place that I had no idea how to use.”

As an undergraduate student, Robertson started working for Dr. Jim Hendry, a geosciences expert known for his work in understanding the movement of chemicals in the subsurface. Under Hendry’s guidance, Robertson became involved in understanding what controls the removal of potential environmental contaminants in uranium processing.

Insight into the exact ongoing chemistry of the treatment process helps companies ensure that they are using the most effective techniques to eliminate potential contaminants.

“We’re providing scientific information that will allow the uranium mills to continue to protect our groundwater from mining operations in the present and for generations onwards,” says Robertson.

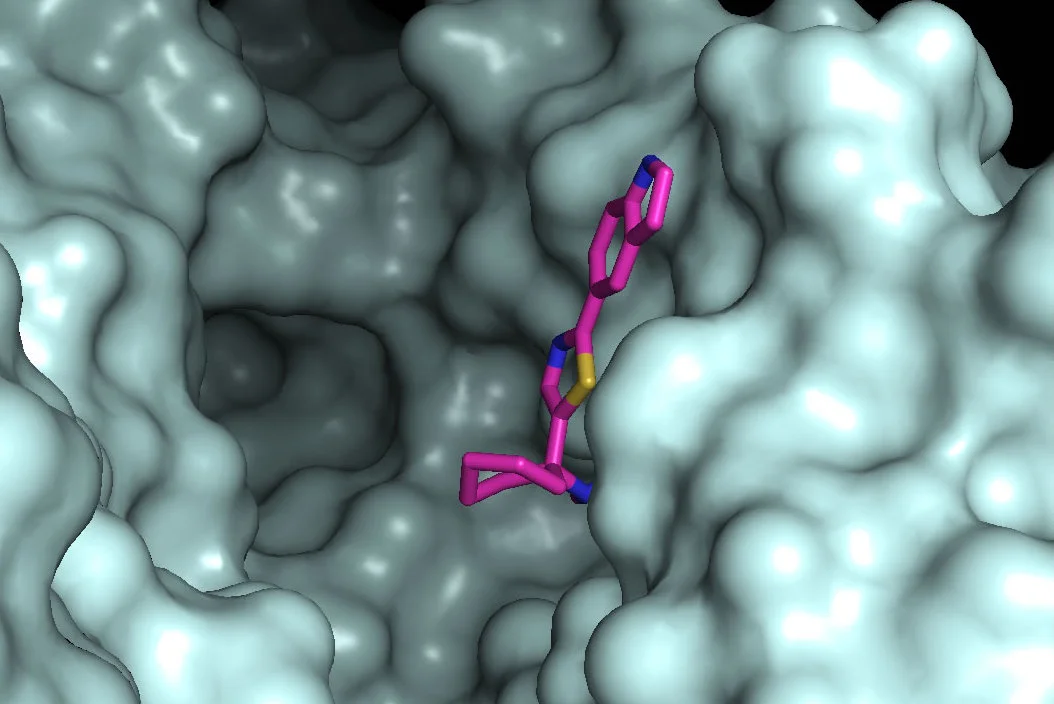

His latest results indicate that aluminum and magnesium, normally-occurring elements in the mill process, can efficiently pull out potential contaminants, including arsenic and molybdenum, as they are removed from the water.

What’s more, the removal of these elements can work in concert with previously known contaminant sponges,” like iron hydroxides, to remove unwanted elements.

Robertson’s research specifically models the water treatment process at the Key Lake uranium mill, but could easily be adjusted to mimic the processes at other uranium mills.

Next up, Robertson’s team will refine their model of chemical reactions to pinpoint how aluminum, magnesium, and iron hydroxides work together to treat mill water. Armed with that information, it will be possible to hone the cleanup process for mills to further improve their environmental safety for up to 10,000 years in the future.

“The interplay between academics and the industrial side of things really allows us to apply our science in a rewarding way,” says Robertson. ”We can transition from just seeing results in the lab to actually be able to talk to industry and see how we can feasibly apply what we have been learning, and seeing where we might need to focus our science in future studies.”

This post first appeared as a Science Highlight for the Canadian Light Source.